The Definitive Guide To Custom Labelling

Ensure your decals, badges, stickers, and other brand labels never fade, never peel and never fall off.

- Section 1: Custom Labelling Essentials

- Section 2: Custom Labelling Types & Materials

- Section 3: Best Applications for Custom Labels

- Section 4: Choosing the Right Label Adhesive

- Section 5: Branding Benefits of Custom Labels

- Section 6: Key Considerations Before Starting Your Labelling Project

- Section 7: The Tale of Two Labels

Custom label solutions go beyond the simple concept of a branded sticker. They encompass the art of designing, producing, and applying labels that are specifically tailored to suit a product’s unique requirements. These labels are crafted to align with a brand’s identity—its colours, fonts, and design—ultimately ensuring the product is represented exactly how the brand intends to be perceived by its target market.

No two custom labels are made the same. They can range from innovative solutions like QR code beacons and vibrant tap tops to name plates, safety compliance plates, and domed labels; the possibilities for custom labels are virtually endless.

In this guide, we will break down the essentials of custom labelling to help you ensure your labels not only look great at production but continue to withstand everything your environment throws at them.

Download This Page as a PDF

Domed Labels

What Are Domed Labels?

Domed labels, also known as raised stickers or 3D stickers, are a standout choice for brands seeking durability and enhanced visual appeal. These labels feature a clear, raised, dome-shaped polyurethane coating that enhances the design and offers added protection against external elements. The raised profile creates an eye-catching, high-end aesthetic while providing resistance to weathering, fading, and peeling.

The polyurethane coating applied to domed labels offers a durable and visually appealing finish. The raised dome effect creates depth and dimension, allowing the label to stand out from flat alternatives. This feature also provides an extra layer of protection against the harmful effects of UV rays, harsh chemicals, and extreme weather conditions.

Imagine a car badge that has had years of exposure to harsh UV rays, rain and tough environments, yet the badge remains vibrant and intact after years – this is the power of a good quality domed label. It speaks for itself.

Polycarbonate Labels

What Are Polycarbonate Labels?

Polycarbonate, often referred to as 'polycarb,' is a tough, lightweight, and virtually indestructible plastic that is commonly used for creating highly durable labels.

Like domed labels, polycarbonate labels offer exceptional resistance to UV rays, chemicals, water, and extreme weather conditions. The key distinction lies in the design—while domed labels have a raised, 3D profile, polycarbonate labels are flatter and more understated.

They are designed to endure harsh environments, maintaining legibility and quality under extreme conditions without compromising visual appeal. For example, polycarbonate labels are commonly used on trucks and heavy machinery for wayfinding and safety warnings. They provide critical information that must remain clear and unfaded for compliance. Their flat design ensures that they are easy to apply to products and surfaces where simplicity is preferred.

Acrylic Cut Labels

What Are Acrylic Cut Labels?

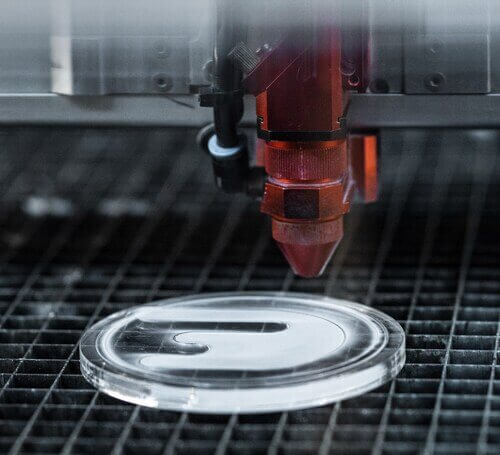

Acrylic cut labels are a type of rigid substrate printing. They are contemporary and highly versatile labelling solutions crafted from acrylic material, precisely cut into custom shapes or designs using advanced laser technology. Unlike domed labels, acrylic cut labels do not need a curved surface and can be shaped into virtually any design, offering enhanced design flexibility. These labels can also feature vibrant, fluorescent colours that create an eye-catching visual appeal.

Acrylic cut labels are laser-cut into precise shapes, enhancing the appearance of products. These labels often showcase a raised 3D effect, making them visually striking while adding depth and dimension. Acrylic labels are ideal for brands aiming to make a bold statement, providing endless design possibilities.

Traffolyte Labels

What Are Traffolyte Labels?

Traffolyte labels, which include nameplates, name tags, and badges, are sought after for engraving applications. Being lightweight and flexible, they are perfect for a variety of uses, such as safety signage, emergency labels, and equipment identification.

One of the key advantages of traffolyte is its ease of use compared to aluminium labels. Being a lightweight material, it is simple to handle and engrave, making it a highly versatile option. Traffolyte is composed of multiple layers of phenolic plastic sheets in various colours. When engraved, the process reveals a contrasting colour beneath, resulting in clear and precise markings. This is beneficial as traffolyte engraving lasts longer as opposed to direct printing onto a top surface that may deteriorate sooner.

However, it’s important to consider the limitations of traffolyte labels. They may not be suitable for environments with extreme weather conditions, such as temperatures exceeding 150°C, or where they will be subjected to high impact or significant stress.

Anodised Aluminium Labels

What Are Anodised Aluminium Labels?

Anodised Aluminium labels, also known as plates, are dependable for long-lasting, corrosion-resistant identification and signage, making them suitable for indoor and outdoor use. They are most commonly used for safety compliance plates that provide essential regulatory and safety information about a product, machine, or system. These plates are typically used in industries where safety is critical, such as manufacturing, construction, and automotive sectors. The information on a safety compliance plate could include certifications, safety warnings, operational instructions, weight limits, serial numbers, QR codes and compliance with regulatory standards.

Benefits of Anodised Plates:

Regulatory Compliance: Provide visible, clear safety instructions and certifications to ensure your business meets legal safety and operational requirements.Durability: Safety compliance plates are designed to withstand extreme conditions such as heat, moisture, and abrasion and will last throughout the equipment's life.

Improved Workplace Safety: Clearly visible safety information reduces the risk of accidents and enhances safety awareness in your workplace.

Self-Adhesive Vinyl

What Are Self-Adhesive Vinyl Labels?

Self-Adhesive Vinyl is a versatile and easy-to-use material commonly used for creating labels, stickers, and decals. As a "peel and stick" product, it features an adhesive backing that allows it to bond to a wide range of surfaces.

The labels are directly printed onto the vinyl surface, providing high-quality, vibrant designs that can be cut to any shape or size based on your needs. Whether you need simple rectangular labels or intricate, custom-cut designs, self-adhesive vinyl is flexible enough to handle various shapes and sizes. Typically, self-adhesive vinyl labels are the most cost-effective option and the most common approach.

However, one important consideration is that self-adhesive vinyl labels are often ‘what you see is what you get’. The colour and appearance of the label are determined by the print job, and there is minimal room for changes once the design is printed. Additionally, while the vinyl is durable, it’s important to note that it is not always suitable for heavy-duty or industrial environments where extreme wear or weather conditions may be a factor.

Self-adhesive vinyl is also highly cost-effective and easy to apply. It requires no additional tools or complex installation processes. Simply peel off the backing and stick the label onto the desired surface, making it perfect for quick and hassle-free applications.

QR Code Labels

QR code labels offer a seamless way to instantly bridge physical products with digital information. Often printed on round acrylic cutouts, commonly referred to as beacons, they are widely used in the hospitality industry for effortless menu access or contactless payments. Beyond this, QR codes are an efficient tool for directing customers to additional product details, service information, or location-based content, enhancing engagement and streamlining user experiences.

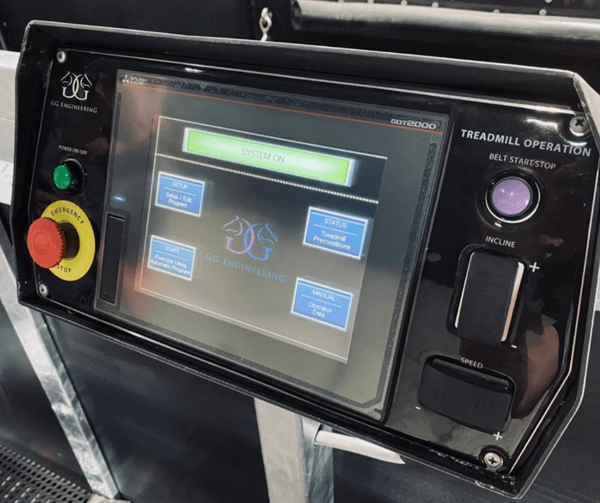

Graphic Overlay

Graphic Overlays are thin, flexible labels that provide a protective layer for the graphics or displays underneath. They are typically used in electronics, control panels, appliances, and machinery. Graphic overlays are often made from materials such as polycarbonate, or are domed, which provide both durability and clarity. These overlays not only protect the printed graphics from damage but also ensure that the visual appearance remains intact for a long period of time.

Graphic overlays can include any design, from simple text to complex multi-coloured patterns, and are often used for user interfaces or branding.

How Polycarb Graphic Overlays Work:

A graphic overlay is designed to be placed over the top of a panel or display. The graphics are printed directly onto the back of the overlay, creating a durable, scratch-resistant surface. The overlay protects the underlying display or controls, such as buttons, screens, or logos, from moisture, dirt, and wear.

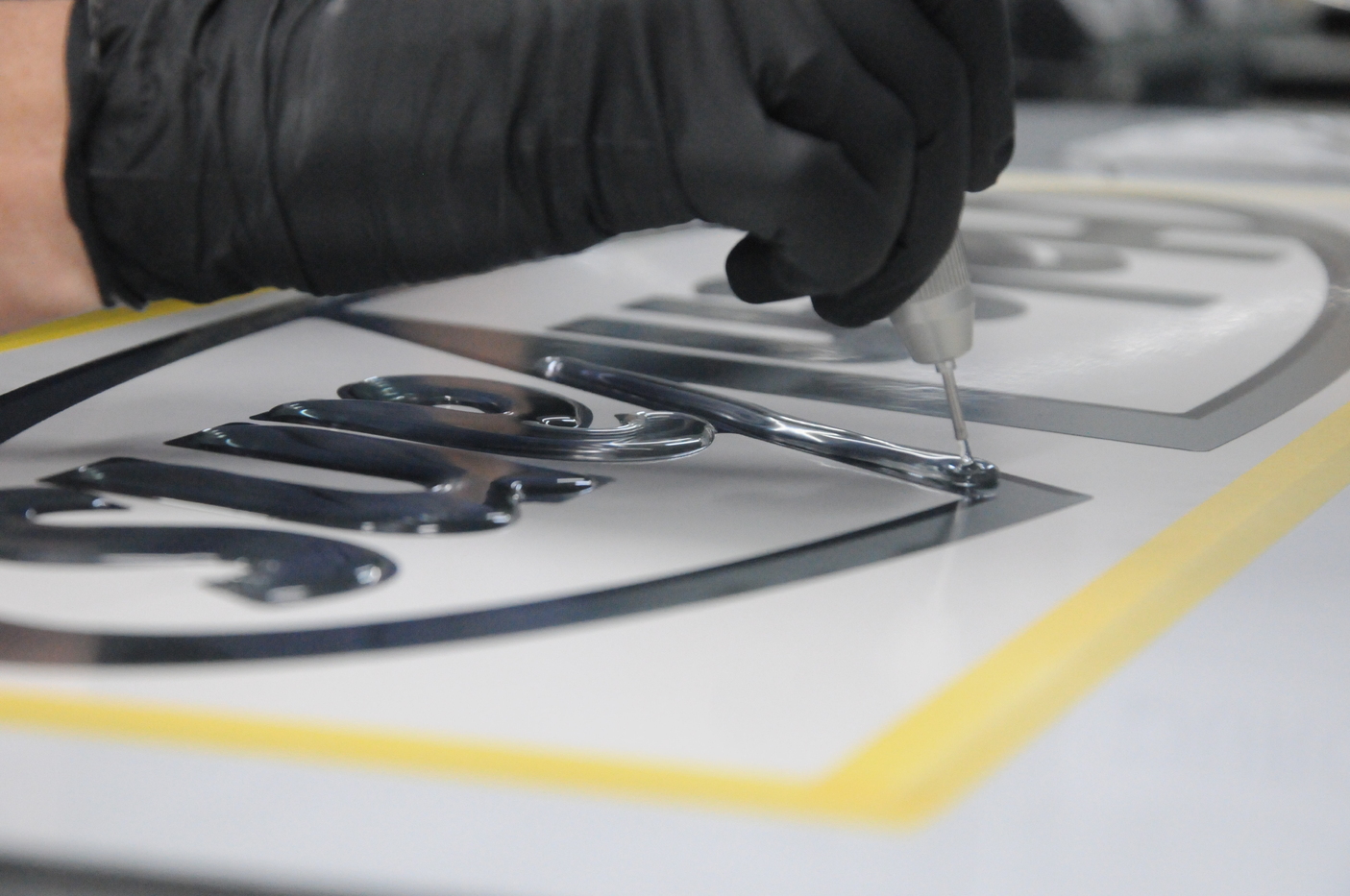

DuroChrome Badging

DuroChrome Badging is a premium labelling solution that combines high durability with a sleek, chrome-like finish. The result is a high-gloss, polished appearance that is visually striking and highly resistant to wear and tear.

DuroChrome Badging is ideal for businesses seeking a luxury aesthetic combined with long-lasting performance.

Tap Tops

Tap tops, also known as tap decals, are custom labels commonly used on beverage containers, drink taps, or dispensing systems. These labels are made from various materials, with the most popular being acrylic and domed finishes, offering both durability and an eye-catching look. Tap tops are designed for branding and interaction, acting as a focal point for consumers when serving or receiving their drinks.

These labels play a key role in elevating the appearance of drink dispensers, reinforcing the brand identity with clear, professional, and informative messaging. Tap tops are highly visible, making them an effective tool for brand promotion. Whether you're looking to highlight a specific product, showcase a logo, or add important product details, Tap Tops can be fully customised to reflect the unique aesthetics of a brand.

Etched Design

Etched labels are a premium labelling solution that involves the removal of material from a surface, typically using a laser, to create a permanent, raised or recessed design. This method produces highly detailed, durable designs that are both visually appealing and long-lasting. Etched labels are often made from materials such as acrylic, bamboo, or timber, which confer a sophisticated aesthetic.

Etching uses precise techniques to carve designs, text, or logos into the material's surface. This permanent method ensures the label will not fade or degrade over time, even under harsh conditions. The etching process creates a textured, elegant appearance that is particularly effective in high-end branding or products requiring a premium look.

Barcode Element

Barcode labels are custom labels that feature a series of parallel lines or squares designed to encode data. These labels are essential tools for tracking, inventory management, and product identification, offering a reliable method for storing information such as product details, pricing, and serial numbers. Typically printed on durable materials like polycarbonate, self-adhesive vinyl, and anodised aluminium, barcode labels provide an efficient and accurate asset tracking and management solution. Their versatility and ease of integration into existing systems make them an invaluable asset for streamlining operations and improving overall efficiency.

Choosing the Right Label Adhesive

Adhesives are an integral part of designing your labels. No matter the material (domed, polycarb, acrylic, etc), the adhesive is simply the glue that bonds your desired labels with the desired surface. All labels must have adhesive. You want to ensure your labels won’t peel or fall off.

Acrylic Foam Adhesives:

Acrylic foam adhesives are an advanced label solution that requires a strong and adaptable bond. These double-sided tapes feature a foam core coated with high-performance acrylic adhesive on both surfaces, offering unparalleled bonding strength and durability.

Acrylic Pressure Sensitive Adhesive (PSA) Tapes

Acrylic PSA tapes are single-sided adhesives designed for specialised applications. With a precise layer of acrylic adhesive, they bond effectively with both high-surface-energy materials like glass and low-surface-energy materials such as polypropylene. Their tack level can be customised, from very low to high, allowing them to be tailored to your specific requirements. These tapes also offer excellent temperature resistance and durability against environmental factors like UV exposure, heat, and humidity. Their adaptability makes them an ideal solution for applications requiring a precise and reliable adhesive.

Self-Adhesive Vinyl

As the name suggests, self-adhesive vinyl combines both the material and adhesive in one. This makes it a popular choice for many consumers, valued for its robust durability and versatility. However, there are two main types of self-adhesive vinyl to consider:

Cast Vinyl

Crafted through a sophisticated process, cast vinyl starts in a liquid state and is evenly distributed into thin sheets before being cured. This method yields a flexible, highly durable material capable of withstanding environmental stress for 5 to 12 years.

Calendered Vinyl

Calendered vinyl is manufactured by extruding vinyl through rollers, which introduces an inherent "memory" to the material. Over time, this characteristic can lead to shrinkage, warping, or cracking, especially under environmental stress. While calendered vinyl may be suitable for short-term applications, it falls short in environments requiring longevity and resilience.

Cast vinyl is often preferred for its superior longevity and resilience when choosing self-adhesive vinyl for custom labels. Understanding your specific needs and consulting with an expert can help ensure the best choice, maximising performance and value.

The Risks of Choosing the Wrong Label Adhesive

Choosing the wrong adhesive can result in significant challenges, each with potential repercussions for your brand and bottom line:

- Label Failure: Poor adhesion leads to peeling, fading, or total detachment, undermining the product’s appearance and usability.

- Product Damage: The wrong adhesive may harm surfaces during removal, necessitating costly repairs or replacements.

- Reputational Damage: Labels that degrade or fail prematurely can erode customer trust, diminishing brand credibility.

- Increased Costs: Replacing faulty or improperly applied labels can escalate production costs, particularly in high-volume operations.

At Durolenz, our expertise ensures that every adhesive is carefully matched to your project's needs. This meticulous approach not only prevents these pitfalls but guarantees labels that endure, protecting your product and reputation.

Supporting Content

Download This Page as a PDF

Branding Benefits of Custom Labels

How Labels Can Increase Awareness and Ultimately Conversions

Over the years, how businesses engage with their customers has evolved dramatically, shifting from a product-first mindset to a customer-centric approach. In today’s competitive landscape, where consumers hold power over communication channels, brands must fight harder than ever for attention. A single misstep in delivering a positive experience can result in damaging reviews or losing high-value customers – outcomes no business can afford.

This makes the customer experience (CX) journey critical from the first touchpoint: awareness. Labels play a pivotal role in shaping that all-important first impression. A well-designed, eye-catching label does more than grab attention – it creates an emotional connection and reinforces brand identity. Each time a consumer encounters your label, it serves as a visual trigger for brand recall. Over time, these consistent and memorable cues don’t just drive awareness; they embed your brand in the minds of your audience, influencing purchasing decisions and building long-term loyalty.

Omnichannel marketing is about delivering a seamless customer experience across every touchpoint, both online and offline, so why overlook your labels? Once you've mapped out your buyer journey and identified what truly matters to your customers, aligning and unifying your brand messaging becomes essential to enhancing CX.

If your audience values quality, every brand element should reflect that standard, including your messaging, packaging, and, critically, your labels. A well-crafted product label isn’t just a detail; it directly represents your brand. If your label feels inconsistent or off-brand, what message does that send? Will customers perceive your brand as one that prioritises quality, or will they question whether their expectations will be met?

Consistency builds trust. Your labels should seamlessly align with your brand’s colours, shapes, and design to maintain recognition and reinforce credibility, key factors in driving conversions. Consider McDonald’s: they wouldn’t compromise on the exact shade of yellow for their iconic ‘M’ because they understand the power of brand consistency. A faded or inaccurate label can erode customer confidence and weaken brand integrity. If brand trust matters, ensuring your labels are an exact match isn’t just a detail. It’s a necessity.

Supporting Content

Brand Consistency is Key

Your labels are an extension of your brand identity. Ensure your logo is prominently and consistently displayed using your brand’s specific colours and fonts. At Durolenz, our in-house design team can assist with all your design needs and ensure your labels perfectly represent your brand.

Define the Label’s Purpose

The design and specifications of your label should align with its intended purpose. Whether it’s a QR code directing customers to a restaurant menu or a safety label for industrial equipment, understanding the label's function is crucial. This clarity helps in selecting the appropriate materials and adhesive options for optimal performance.

Select the Right Finishes

The choice of finish can significantly enhance the appeal of your labels. Options range from glossy domed finishes to etched, acrylic laser-cut, chrome, or fluorescent designs. The possibilities are nearly limitless, allowing you to tailor the finish to align with your brand and desired aesthetic. Keep in mind you may require different finishes for indoor vs outdoor applications.

Short or Long Term Performance

The choice of substrate and adhesive depends on your label's intended lifespan and function. A short-term, removable label designed to last just a few months will require significantly different materials than a premium domed label with acrylic PSA tape, built for outdoor durability and high UV resistance. To ensure your labels perform as expected, consult with experts who can guide you toward the best solution for your specific needs.

Order Deadlines and Proofing before Production

At Durolenz, we prioritise fast turnaround times without compromising on quality. To ensure a smooth process, we work with our clients to understand all order details, including the required delivery date and specific deadlines. Clear communication allows us to meet your timeframe efficiently.

Submit Artwork in the Best Format

For the best results, submit your artwork in vector format, this is typically a file with .ai / .eps or .pdf in some cases. If you’re uncertain about the final design, request a proof from your supplier. This step ensures you’re satisfied with the design before production begins, preventing delays and ensuring a flawless outcome.

What now?

Once you've finalised your order and are ready to proceed, it’s crucial to prepare the application surface properly. While often overlooked, this step is essential for achieving the best possible adhesion.

Before applying your labels, ensure the surface is clean, dry, and free from dust, dirt, or grease. Use a lint-free cloth to wipe it down thoroughly. This will help the adhesive bond effectively, ensuring a secure and long-lasting application. Keep in mind that maximum adhesion is achieved 24 hours after application.

Our team is always available to assist if you have any questions or concerns.

The Tale of Two Labels

Ultimately, when choosing custom labels, most choices fall into two categories, and your decision will impact your brand significantly.

The first option is high-quality labels that are designed with longevity in mind. Crafted from premium materials, they maintain vibrant colours, crisp details, and strong adhesion. More importantly, they withstand environmental stressors like UV exposure, moisture, and abrasion, ensuring your products are represented as you want to be perceived. Choosing the premium option ensures you won't be second-guessing or replacing your labels in the short term.

The second option falls into the category of “buy nice or buy twice’, where the sentiment is that taking a shortcut with a cheap alternative invariably requires a replacement for a high-quality solution. Such cheap alternatives are typically more prone to fading, peeling, and losing adhesive strength, resulting in a diminished brand appearance, product recalls, and frequent replacements. A poor label can make even a premium product feel cheap, eroding customer trust and weakening brand perception.

Making the right choice from the outset isn’t just about aesthetics; it’s about long-term brand consistency. While a lower-cost label may offer short-term savings, a high-quality label safeguards your brand’s reputation, reduces replacement costs, and enhances the customer experience. In branding, every detail matters, so choose labels that uphold your brand’s integrity from the very first impression.

From Our Blog

Stay up to date with what our latest custom labelling insights.

Make Your Products Better Than Your Competitors : Custom Labels

Traditional vs Domed Labels: Why Marketers are Making the Switch